Weighing instrument refers to the instrument in the electronic scale that displays the weight and weighing status of the object to be weighed. Weighing instrument is also called weighing display control instrument.It is an electronic device that converts the signal of the weighing sensor (or through the weight transmitter) into a digital display of weight, and can store, count and print the weight data.It is often used for automated batching and weighing in industrial and agricultural production to improve production efficiency.

Working principle of weighing instrument

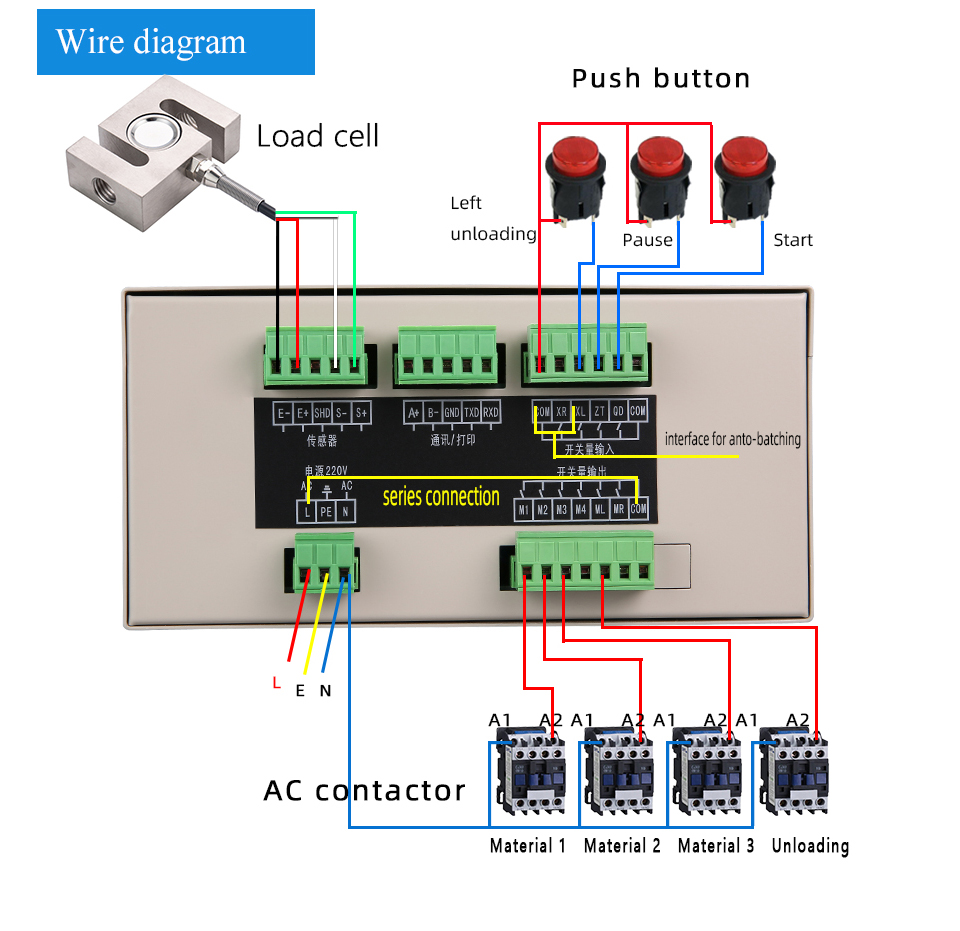

Electronic weighing systems generally consist of scale bodies, load cells, junction boxes, weighing display instruments and other parts.Its working principle is shown in the figure below:First, multiple load cells collect the weight signals from the sensing weights through a junction box and then enter the instrument (if there is only one sensor for one scale in the weighing system, there is no need for a junction box for signal aggregation).The instrument amplifies, filters and A/D converts the weight signal (mV level), and then displays the weighing signal on the digital screen through digital processing.In addition, for systems that need to connect signals to PLC, touch screens, computers, printers and other equipment, the weighing instrument will also output different signals through interface circuits to transmit weight data and control signals to other system equipment.In order to meet the versatility and convenience of the instrument, weighing instruments generally also add setting correction functions, zero-setting tare functions, zero-point tracking functions, preset point output functions, etc.

Performance characteristics

The performance of Preston weighing instruments includes five aspects: measurement performance, functional environmental adaptability, safety and reliability.Compared with general digital weighing instruments, digital display has 5 characteristics:

① Comes with sensor excitation power supply, easy to use;

② Adopting ratio-type A/D conversion and frequency conversion technology, the measurement performance is stable;

③The software can truly simulate vibration, empty scale changes, material drop and other weighing characteristics, and the display is fast, accurate and stable;

④The machine has setting units for empty scale zeroing, zero tracking, calibration, maximum weighing indexing and other parameters, which are easy to change and have strong versatility;

⑤With output interface, it can connect to a variety of external devices to facilitate system control.

Weighing instrument fault identification method:

Since the failure phenomena of weighing instruments are diverse and there are many causes of failures, to troubleshoot weighing instrument failures, you must first be familiar with the working principle of the weighing instrument and the functions and judgment methods of each component.Check the source of the fault one by one through the devices related to the fault phenomenon to determine the location of the fault.Here are some common methods for you to use when troubleshooting.

Observation method

Observation method" is a method of direct inspection through human senses to find the cause of the fault. There are usually several methods of sight, hearing, and touching:Visual inspection is to observe whether the wiring between the instrument and the sensor (junction box) is normal, and whether the power supply and control lines are connected normally.Check whether there are broken wires, bumps, short circuits, etc., and observe whether there is any burnt inside the instrument, whether there is water ingress, and whether the fuse is disconnected, etc.Listening means listening carefully for any abnormal noise inside the instrument. Touch by hand, that is, touch the transformer wire package, filter capacitor and other components to see if the temperature is abnormal.

2.Plug and pull method

The "plug and pull method" is a method of unplugging a certain component and plugging in a simulated component to see where the fault is and find the cause of the fault.For example, if the weighing instrument display is unstable, unplug the connecting cable from the junction box (load sensor) to the instrument, and connect the simulator. When the instrument reading returns to stability, it indicates that the problem lies in the junction box or sensor. Otherwise, look for problems with the instrument.

3.Substitution method

Substitution method "Substitution method" is to use normal components, circuit boards, etc. to replace suspected faulty parts and see if they return to normal after replacement, so as to find out the cause of the fault.

4.Comparative method

The "comparison method" is to use instruments such as multimeters and oscilloscopes to measure the voltage, resistance, waveform and other data of components with suspected faults, and compare them with normal values to determine whether the components are faulty.

static feature measurement method

5.Measurement method

"Measurement method" is a method that uses a multimeter to measure the level of each point of the instrument in a specific state, and then analyzes and determines the cause of the fault based on logical principles.

6.Code Diagnosis Method

"Code diagnosis method" is a judgment method to find out the problem through the error code obtained by the instrument's self-diagnosis.Don’t panic when encountering problems with the weighing system. First, avoid blindly looking for reasons without basis.The cause of the failure should be judged from the entire principle of the weighing instrument and weighing system, and the parts that may cause the problem should be narrowed down and investigated step by step, and finally the fault can be eliminated quickly and accurately.