A load cell is a device that converts a mass signal into a measurable electrical signal output.When using a sensor, you must first consider the actual working environment in which the sensor is located. This is crucial to selecting the correct weighing sensor. It is related to whether the sensor can work normally, the safety and service life of the sensor, and even the reliability and safety of the entire weighing instrument.There are qualitative differences between the old and new national standards in the basic concepts and evaluation methods of the main technical indicators of load cells.

raditionally, load sensors are collectively referred to as load cells and force measuring sensors, and a single parameter is used to evaluate their measurement characteristics.The old national standard combines the two sensors "weighing" and "force measuring" with completely different application objects and usage environmental conditions into one, and does not distinguish between test and evaluation methods.The old national standard has a total of 21 indicators, all of which are tested at normal temperature; and the maximum error among the six indicators of nonlinearity, hysteresis error, repeatability error, creep, zero temperature additional error and rated output temperature additional error is used,to determine the accuracy level of the weighing sensor, they are represented by 0.02, 0.03, and 0.05 respectively.

A force sensor used on weighing instruments.It can convert the gravity acting on the measured object into a measurable output signal in a certain proportion.Taking into account the impact of gravity acceleration and air buoyancy on conversion at different locations of use, the performance indicators of the load cell mainly include linear error, hysteresis error, repeatability error, creep, zero-point temperature characteristics and sensitivity temperature characteristics, etc.

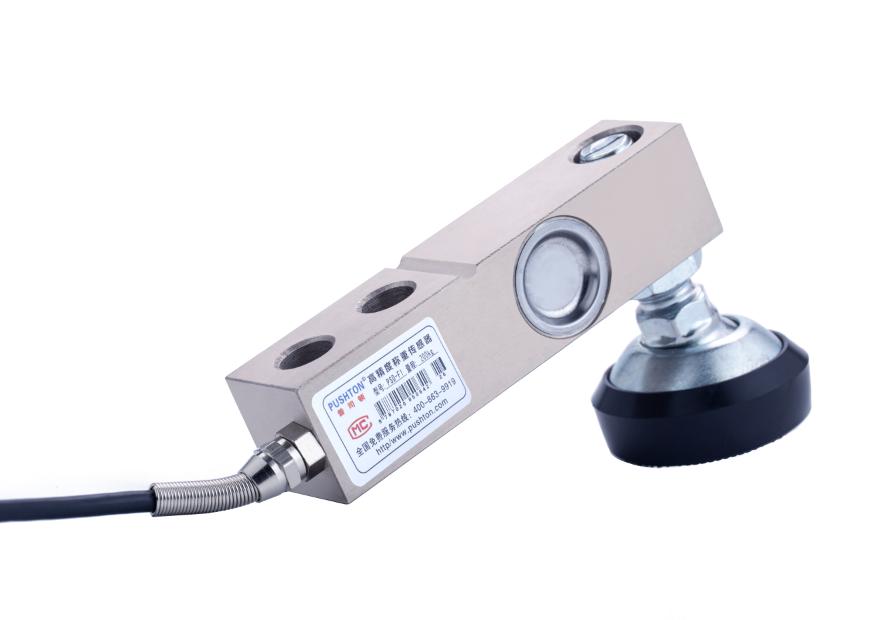

A load cell usually consists of a spring element, usually made of steel or aluminum, on which a strain gauge is placed.This means it is strong but has little elasticity.As the name suggests, a "spring element" means that the steel deforms slightly under load, but then returns to its original position, being elastic for every load.These tiny changes are captured by strain gauges, whose deformations are interpreted by analytical electronics to determine weight.o how to choose a load cell?

Capacity: In addition to the measured load to be measured, the initial load, impact coefficient and load eccentricity coefficient should also be considered.Therefore, the capacity of the selected load cell should be at least 10% higher than the load to be measured.

Dynamic range: In practical applications of electronic weighing systems, multiple sensors are often used simultaneously.Therefore, the sensor is generally designed to work at about 80% to 85% of the rated load, which leaves a safety margin and ensures its accuracy.If you choose a very high capacity sensor, you may not be able to measure very small loads very accurately.As a rule of thumb, the load to be tested should be 10% to 90% of the rated capacity.

Shape: The shape of the load cell mainly depends on its application and installation arrangement.For example, the S-type is suitable for applications where force is applied to both ends, while the diaphragm type is suitable for applications where force is applied to only one end.

Selection of sensor sealing status: The use environment is relatively harsh, and it is often necessary to choose a sealed sensor to protect the sensor from the external environment.Use electronic load cells, such as humidity, dust, corrosive gases, etc., to ensure the accuracy and stability of measurement.

Additionally, other specifications such as rated output, temperature range, tolerances, and protection levels should be noted.