Weighing instruments are usually classified according to their uses, such as electronic belt scales, quantitative belt scales, electronic hopper scales, electronic truck scales, electronic track scales, electronic crane scales,Weight sorting scale, price label scale, quantitative packaging scale, intelligent combination scale, quantitative accumulation scale, reduction scale, liquid filling scale, postal scale, electronic forklift scale, screw feeder scale, rotor feeder scale, continuous weight loss Scales and more.

Electronic belt scale

The electronic belt scale installs a scale frame at a suitable position on the belt conveyor to measure the force of gravity on the scale frame and the belt speed when the material passes through the belt conveyor, and then obtains the instantaneous flow rate of the material in the secondary instrument. and cumulative traffic.

The purpose of the electronic belt scale generally determines the required accuracy. The process monitoring scale does not have high requirements for measurement accuracy, usually 1% to 3%; the measuring scale is used for measuring important raw materials of the enterprise or for internal economic accounting of the enterprise. The accuracy requirements are relatively high, generally 0.5% to 1%; trade settlement scales are used for measuring materials between enterprises, and have the highest measurement accuracy requirements, which should reach 0.25% to 0.5%. The intended use of the belt scale generally determines its required accuracy, but exact accuracy requirements still need to be put forward before selection.

2. Quantitative belt scale

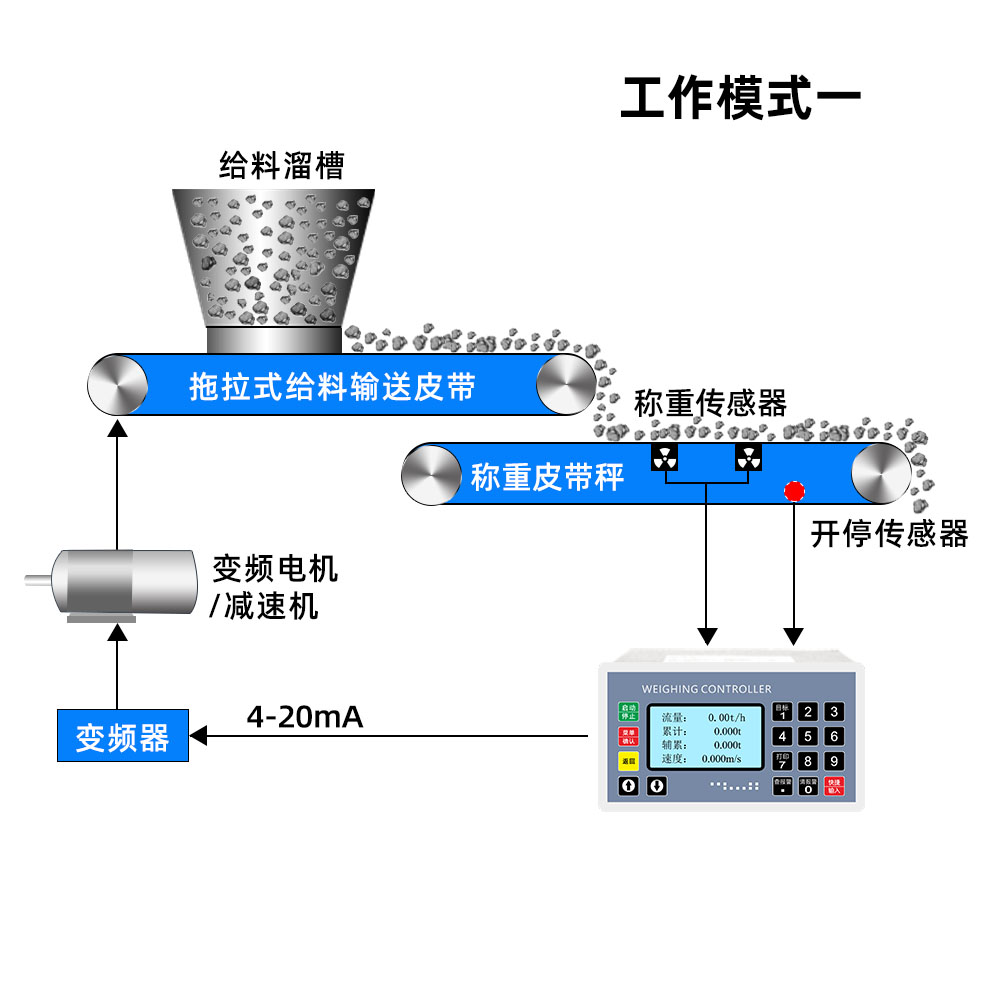

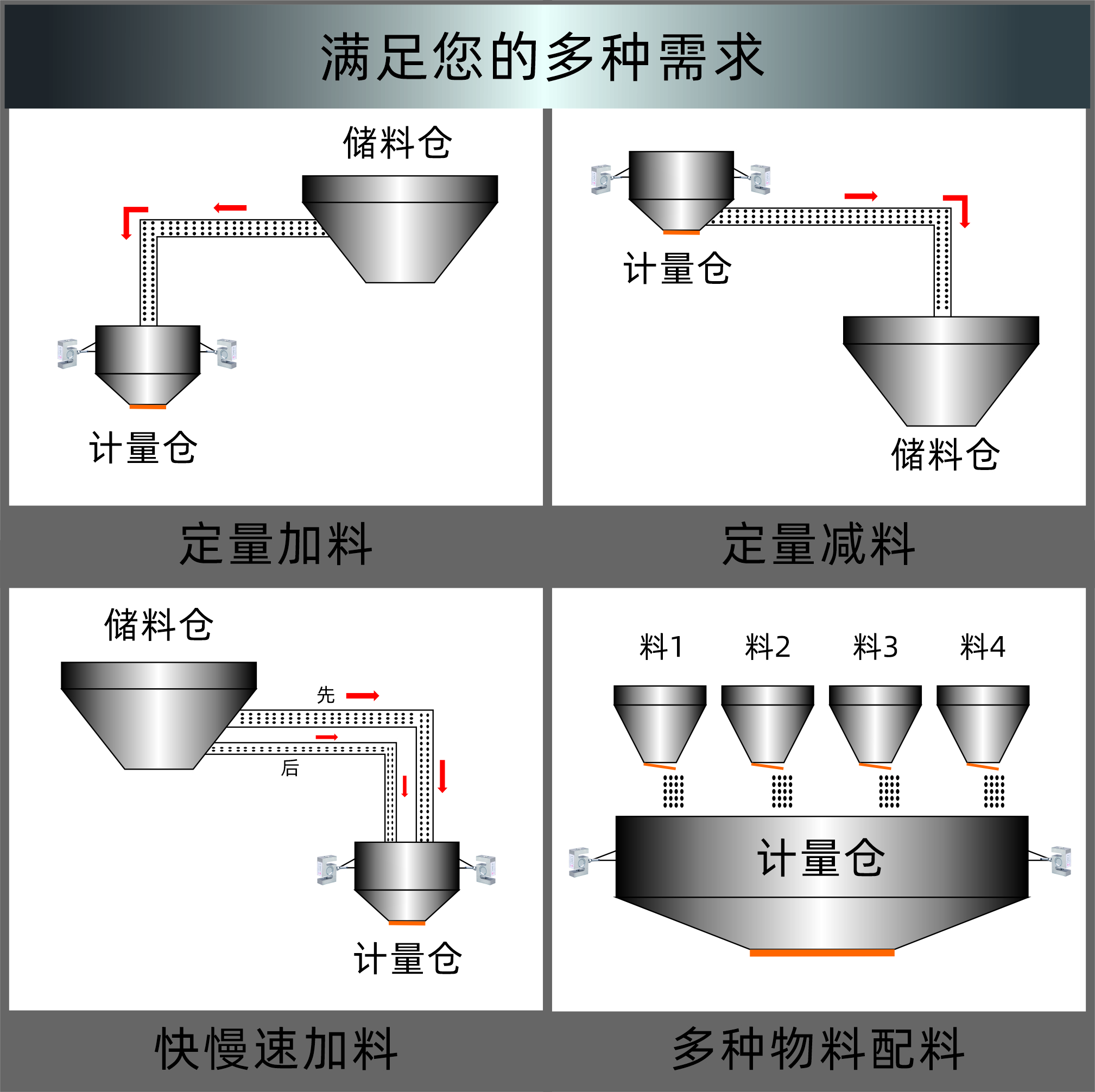

Quantitative belt scale is a special application method of electronic belt scale. In addition to completing the weighing task of material quantity like the electronic belt scale, it also needs to realize the automatic control task of quantitative or proportioning of material quantity. It is usually a short belt conveyor provided by the manufacturer alone, and is equipped with equipment such as a frequency converter to control the material volume.

For materials with good flow properties and moderate humidity, no pre-feeding device is required when using a drag belt scale; for granular materials with viscosity and a small amount of moisture, disc feeders and electromagnetic vibrating feeders can be selected; dry For fine powdery materials, screw feeder, sealed impeller feeder and flow control valve can be selected.

The selection of measuring range should not be too large or too small. Since the amount of materials in the production process tends to increase, a measuring range that is too small cannot do anything about it.However, the measuring range is too large. In order to maintain a certain belt speed during actual batching, the thickness of the material layer on the belt is too thin, which is not conducive to ensuring batching accuracy.

Under the condition of maintaining a constant material layer thickness, the quantitative belt scale can usually ensure the accuracy of the ingredients within the motor frequency conversion speed regulation range of 10:1.

When designing and selecting, try to keep the actual amount of ingredients used within the range of 20% to 80% of the range, and a margin of more than 20% can be added to ensure the belt speed.It should be noted that the existing material layer thickness on the belt should also be thickened by 20% to 30%. As a last resort, the measuring range can be expanded by increasing the feeding amount or raising the feeding gate.

3. Electronic truck scale

Electronic truck scales are large scales set on the ground. They are used to weigh the cargo weight of trucks. They are also commonly called floor scales. They are used in bulk material measurement industries such as metallurgy, mining, chemical industry, grain, logistics, coal, etc. for factories and mines. It is the main weighing equipment for cargo measurement and government highway overtaking control.

The maximum weighing capacity should be selected to be greater than the sum of the weight of the goods being weighed and the weight of the vehicle itself, and the maximum allowable total load of the weighing platform should be less than the sum of the maximum weighing capacities of all the load cells of the truck scale.